Your current browser version is too low, in order to bring you a better browsing effect, please use a higher version browser

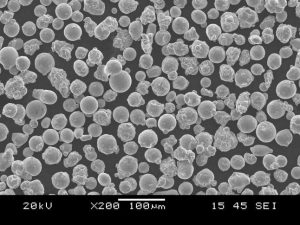

Vacuum gas atomization and plasma spheroidization technology are introduced to produce spherical powder such as Fe-based, Ni-based, Co-based, W, Mo, Ti and Ti alloy for AM.Also AM service chain can be provided from spherical metal powder preparation, AM verification, hot isostatic pressing and densification.

We have rich experience in additive manufacturing, and can provide customized service on the gas atomized and plasma spheroidized metal powder. The metal powders have the characteristics of low cost, low oxygen content, less satellite powder, high sphericity and high fluidity.

The metal powder can be applied for Direct Metal Deposition(DMD), Direct Metal Laser Sintering(DMLS), Selective Laser Sintering(SLS) and Selective Electron Beam Melting(SEBM), etc.

Component of CoCrMo

|

Element |

Co |

Cr |

Mo |

W |

S |

Fe |

Mn |

|

Content |

61.8 – 65.8 |

23.7 –25.7 |

4.6 – 5.6 |

4.9 – 5.9 |

0.8 – 1.2 |

max. 0.50 |

max. 0.10 |

Properties of CoCrMo Powder

|

Oxygen Content ppm |

Apparent Density g/cm3 |

Particle Size D50/um |

|

182 |

4.33 |

35.728 |

Properties After Heat Treatment

|

|

Tensile Strength,σb, MPa |

Yield Strength,σ0.2,MPa |

Elongation,% |

|

1 |

1170 |

876 |

22.5 |

|

2 |

1159 |

855 |

22.4 |

Orthopaedic Implants of CoCr-Alloy by AM

| Powder Material System | Typical Grade | Powder Particle Size, (D10-D90) μm | Preparation Process |

| Iron-based alloy | 316,316L,17-4PH,15-5PH,18Ni300 | 15-53, | Aerosolization |

| 10-45, | |||

| 75-150, | |||

| customizable | |||

| F | 625,718,K series | 15-53, | Aerosolization |

| 10-45, | |||

| 75-150, | |||

| customizable | |||

| Cobalt-based alloy | CoCrMo,CoCrWMo | 15-53, | Aerosolization |

| 10-45, | |||

| 75-150, | |||

| customizable | |||

| Titanium and titanium alloys | Pure Ti, TC4, TC18, TC21, TA15, TA18 | 15-53, | Hydrodehydrogenation + plasma spheroidization |

| 10-45, | |||

| 75-150, | |||

| customizable | |||

| Refractory metals such as tungsten | W,Mo,Ta,Nb | 15-53, | Reduction of fragmentation + plasma spheroidization |

| 10-45, | |||

| Alloy Powder | Typical Alloy | Particle Diameter,(D10-D90),μm | Fabrication Methods |

| Fe-base Alloy | 316,316L,17-4PH,15-5PH,18Ni300 | 15-53, | Gas Atomization |

| 10-45, | |||

| 75-150, | |||

| Customed | |||

| Ni-base alloy | 625,718,K-series | 15-53, | Gas Atomization |

| 10-45, | |||

| 75-150, | |||

| customization | |||

| Co-base alloy | CoCrMo,CoCrWMo | 15-53, | Gas Atomization |

| 10-45, | |||

| 75-150, | |||

| customization | |||

| Ti & Ti alloy | pure-Ti,TC4,TC18,TC21,TA15,TA18 | 15-53, | HDH+Plasma spheroidization |

| 10-45, | |||

| 75-150, | |||

| customization | |||

| W and refractory metal | W,Mo,Ta,Nb | 15-53, | Reduction and fragmentation+Plasma spheroidization |

| 10-45, |