Your current browser version is too low, in order to bring you a better browsing effect, please use a higher version browser

NdFeB permanent magnet has extremely high properties (high residual induction, coercive force and energy product) with really competitive price. It can be machined into all kinds of shapes easily and used in many fundamental fields directly, such as new energy, vehicles, electron & electroacoustic, energy saving household appliances, industrial motor, instrument & apparatus, nuclear magnetic resonance, magnetic suspension field and so on. Magnets are also suitable for the high property, mini-size and lighted products.

AT&M is a magnetic material supplier with R&D, production and sales ability. We are providing top level magnets with customized coatings, weights and shapes. We also provide the design program, great service and technical support during all life cycle.

AT&M has great power in R&D and holds Hitachi license. We have two production bases in Beijing and Shandong producing high grade magnets. The total capacity reaches 6000t. For the past several year, we supplied top level products and service to the customers including the world top 500 enterprises.

Typical applications are as below:

• vehicle

EPS motor/drive motor/electricity generator/pump/sensors

• electronics

mobile/digital camera/hard disk drive/CD drive

• automation

servo motor/elevator motor/liner motor/electric tools

• energy

wind power

• environment

inverter air-conditioner/refrigerator/washing machine

• medical technology

nuclear magnetic resonance/CT scanner/ventilator

• aerospace & ship

ship powertrain

• railway

electricity powertrain

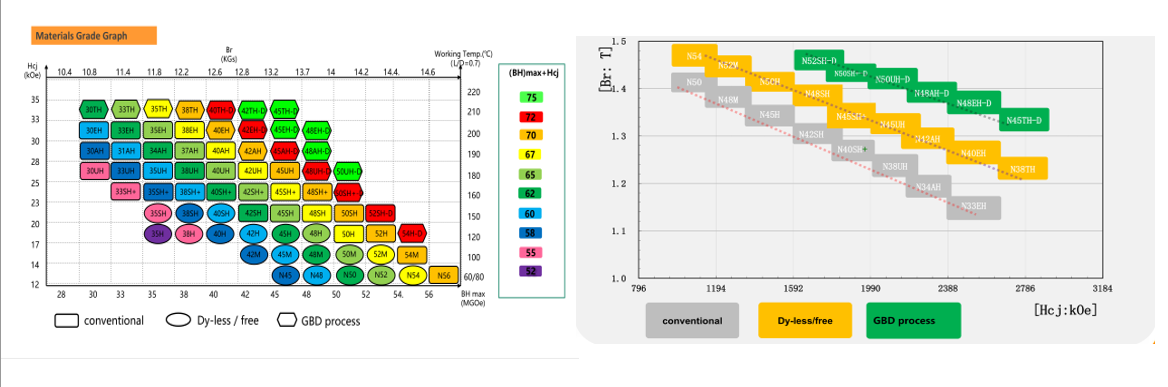

| AT&M Materials Grade Chart | ||||||||

| Grade | Br | Hcb / ≥ | Hcj / ≥ | (BH)max | ||||

| T | KGs | kA/m | kOe | kA/m | kOe | kJ/m³ | MGOe | |

| ATMAX42 | 1.28~1.34 | 12.8~13.4 | 876 | 11.0 | 955 | 12 | 318~342 | 40~43 |

| ATMAX45 | 1.32~1.38 | 13.2~13.8 | 876 | 11.0 | 955 | 12 | 342~366 | 43~46 |

| ATMAX48 | 1.36~1.43 | 13.6~14.3 | 836 | 10.5 | 955 | 12 | 358~390 | 45~49 |

| ATMAX50 | 1.39~1.46 | 13.9~14.6 | 836 | 10.5 | 955 | 12 | 374~406 | 47~51 |

| ATMAX52 | 1.42~1.48 | 14.2~14.8 | 836 | 10.5 | 955 | 12 | 390~422 | 49~53 |

| ATMAX54 | 1.44~1.51 | 14.4~15.1 | 836 | 10.5 | 955 | 12 | 398~438 | 50~55 |

| ATMAX56 | 1.46~1.53 | 14.6~15.3 | 836 | 10.5 | 955 | 12 | 414~454 | 52~57 |

| ATMAX42M | 1.28~1.34 | 12.8~13.4 | 938 | 11.8 | 1114 | 14 | 318~342 | 40~43 |

| ATMAX45M | 1.32~1.38 | 13.2~13.8 | 976 | 12.2 | 1114 | 14 | 342~366 | 43~46 |

| ATMAX48M | 1.36~1.43 | 13.6~14.3 | 1012 | 12.7 | 1114 | 14 | 358~390 | 45~49 |

| ATMAX50M | 1.39~1.46 | 13.9~14.6 | 1035 | 13.0 | 1114 | 14 | 374~406 | 47~51 |

| ATMAX52M | 1.42~1.48 | 14.2~14.9 | 1042 | 13.1 | 1114 | 14 | 382~422 | 48~53 |

| ATMAX40H | 1.25~1.31 | 12.5~13.1 | 912 | 11.5 | 1353 | 17 | 302~326 | 38~41 |

| ATMAX42H | 1.28~1.34 | 12.8~13.4 | 938 | 11.8 | 1353 | 17 | 318~342 | 40~43 |

| ATMAX45H | 1.32~1.38 | 13.2~13.8 | 976 | 12.2 | 1353 | 17 | 342~366 | 43~46 |

| ATMAX48H | 1.36~1.43 | 13.6~14.3 | 1000 | 12.6 | 1353 | 17 | 358~390 | 45~49 |

| ATMAX50H | 1.39~1.46 | 13.9~14.6 | 1035 | 13 | 1353 | 17 | 374~406 | 47~51 |

| ATMAX52H | 1.42~1.48 | 14.2~14.9 | 1042 | 13.1 | 1274 | 16 | 382~422 | 48~53 |

| ATMAX38SH | 1.21~1.27 | 12.1~12.7 | 886 | 11.1 | 1592 | 20 | 287~310 | 36~39 |

| ATMAX40SH | 1.25~1.31 | 12.5~13.1 | 912 | 11.5 | 1592 | 20 | 302~326 | 38~41 |

| ATMAX45SH | 1.32~1.38 | 13.2~13.8 | 976 | 12.2 | 1592 | 20 | 342~366 | 43~46 |

| ATMAX48SH | 1.36~1.43 | 13.6~14.3 | 1000 | 12.6 | 1592 | 20 | 358~390 | 45~49 |

| ATMAX50SH | 1.39~1.46 | 13.9~14.6 | 1035 | 13 | 1592 | 20 | 374~406 | 47~51 |

| ATMAX48SH-D | 1.36~1.43 | 13.6~14.3 | 1000 | 12.6 | 1592 | 20 | 358~390 | 45~49 |

| ATMAX50SH-D | 1.39~1.46 | 13.9~14.6 | 1035 | 13 | 1592 | 20 | 374~406 | 47~51 |

| ATMAX52SH-D | 1.42~1.49 | 14.2~14.9 | 1050 | 13.2 | 1592 | 20 | 390~422 | 49~53 |

| ATMAX54SH-D | 1.44~1.51 | 14.4~15.1 | 1058 | 13.3 | 1592 | 20 | 390~422 | 50~55 |

| ATMAX35UH | 1.16~1.22 | 11.6~12.2 | 845 | 10.6 | 1990 | 25 | 263~287 | 33~36 |

| ATMAX38UH | 1.21~1.27 | 12.1~12.7 | 886 | 11.1 | 1990 | 25 | 287~310 | 36~39 |

| ATMAX40UH | 1.25~1.31 | 12.5~13.1 | 912 | 11.5 | 1990 | 25 | 302~326 | 38~41 |

| ATMAX42UH | 1.28~1.34 | 12.8~13.4 | 938 | 11.8 | 1990 | 25 | 318~342 | 40~43 |

| ATMAX45UH | 1.31~1.37 | 13.1~13.7 | 976 | 12.2 | 1990 | 25 | 342~366 | 43~46 |

| ATMAX45UH-D | 1.31~1.37 | 13.1~13.7 | 976 | 12.2 | 1990 | 25 | 342~366 | 43~46 |

| ATMAX48UH-D | 1.36~1.43 | 13.6~14.3 | 1000 | 12.6 | 1990 | 25 | 358~390 | 45~49 |

| ATMAX50UH-D | 1.39~1.46 | 13.9~14.6 | 1035 | 13 | 1990 | 25 | 374~406 | 47~51 |

| ATMAX31AH | 1.09~1.16 | 10.9~11.6 | 772 | 9.7 | 2149 | 27 | 231~263 | 29~33 |

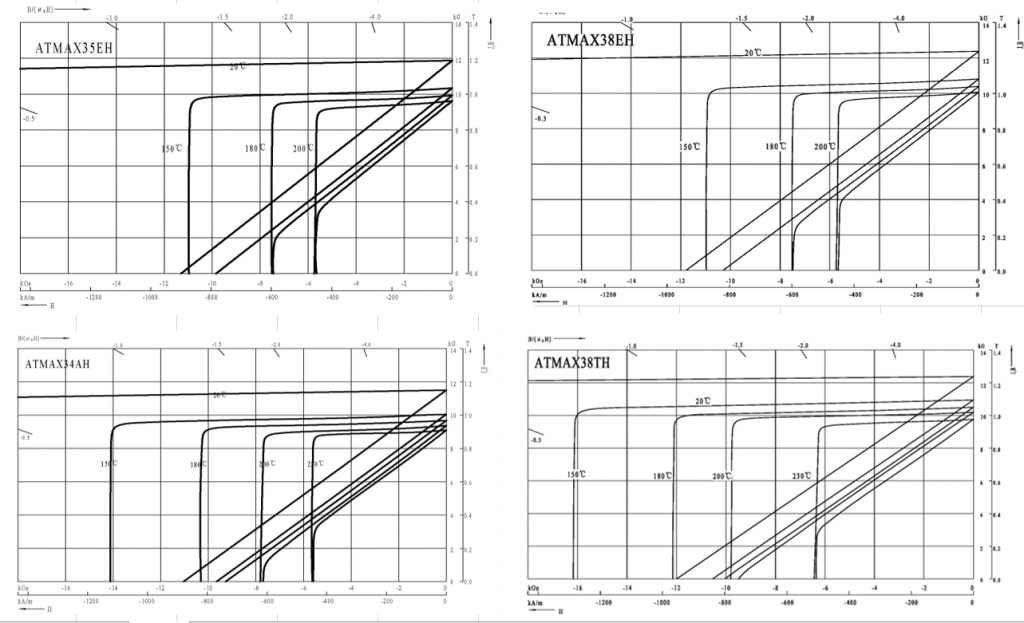

| ATMAX34AH | 1.15~1.22 | 11.5~12.2 | 836 | 10.5 | 2149 | 27 | 255~287 | 32~36 |

| ATMAX37AH | 1.20~1.26 | 12.0~12.6 | 886 | 11.1 | 2149 | 27 | 279~310 | 35~39 |

| ATMAX40AH | 1.25~1.31 | 12.5~13.1 | 912 | 11.5 | 2149 | 27 | 302~326 | 38~41 |

| ATMAX42AH | 1.28~1.34 | 12.8~13.4 | 938 | 11.8 | 2149 | 27 | 318~342 | 40~43 |

| ATMAX42AH-D | 1.28~1.34 | 12.8~13.4 | 938 | 11.8 | 2149 | 27 | 318~342 | 40~43 |

| ATMAX45AH-D | 1.32~1.38 | 13.2~13.8 | 976 | 12.2 | 2149 | 27 | 342~366 | 43~46 |

| ATMAX48AH-D | 1.35~1.42 | 13.5~14.2 | 1000 | 12.6 | 2149 | 27 | 358~390 | 45~49 |

| ATMAX30EH | 1.07~1.14 | 10.7~11.4 | 772 | 9.7 | 2388 | 30 | 223~247 | 28~31 |

| ATMAX33EH | 1.12~1.19 | 11.2~11.9 | 816 | 10.2 | 2388 | 30 | 247~271 | 31~34 |

| ATMAX35EH | 1.16~1.22 | 11.6~12.2 | 845 | 10.6 | 2388 | 30 | 263~287 | 33~36 |

| ATMAX38EH | 1.21~1.27 | 12.1~12.7 | 886 | 11.1 | 2388 | 30 | 279~310 | 35~39 |

| ATMAX40EH | 1.25~1.31 | 12.5~13.1 | 912 | 11.5 | 2388 | 30 | 302~326 | 38~41 |

| ATMAX40EH-D | 1.25~1.31 | 12.5~13.1 | 912 | 11.5 | 2388 | 30 | 302~326 | 38~41 |

| ATMAX42EH-D | 1.28~1.34 | 12.8~13.4 | 938 | 11.8 | 2388 | 30 | 318~342 | 40~43 |

| ATMAX45EH-D | 1.32~1.38 | 13.2~13.8 | 976 | 12.2 | 2388 | 30 | 342~366 | 43~46 |

| ATMAX48EH-D | 1.35~1.42 | 13.5~14.2 | 1000 | 12.6 | 2388 | 30 | 342~366 | 43~46 |

| ATMAX30TH | 1.06~1.15 | 10.6~11.5 | 765 | 9.6 | 2627 | 33 | 223~255 | 28~32 |

| ATMAX33TH | 1.12~1.19 | 11.2~11.9 | 816 | 10.2 | 2627 | 33 | 247~271 | 31~34 |

| ATMAX35TH | 1.16~1.22 | 11.6~12.2 | 845 | 10.6 | 2627 | 33 | 263~287 | 33~36 |

| ATMAX38TH | 1.21~1.27 | 12.1~12.7 | 886 | 11.1 | 2627 | 33 | 279~310 | 35~39 |

| ATMAX40TH-D | 1.25~1.31 | 12.5~13.1 | 912 | 11.5 | 2627 | 33 | 302~326 | 38~41 |

| ATMAX42TH-D | 1.28~1.34 | 12.8~13.4 | 938 | 11.8 | 2627 | 33 | 318~342 | 40~43 |

| ATMAX45TH-D | 1.32~1.38 | 13.2~13.8 | 976 | 12.2 | 2627 | 33 | 342~366 | 43~46 |

| Coating Type | Physical Properties | Environment of Magnet Application | Thickness of Coating Layer | Pictures |

| Zinc | Layer with three kinds of color: silver, blue and white, rainbow etc.Coating layer is compact, stable and homogeneous. | Suitable for common environment. | 4µm ~ 10µm |  |

| Nickel | Homogeneous and Light yellow layer. | NiCuNi:Excellent corrosion resistance. Superior resistance against humidity and heat. | 15µm ~ 30µm |  |

| Epoxy | Black, gray layer with certain luster. | Suitable for higher corrosive environment. |

≥15µm |  |

| Al | The coating has silver-white metallic luster, uniform color and clean surface | It is used in high anti-corrosion occasions, and the coating has no shielding effect on magnetic properties. | 10µm ~ 25µm |  |

| Passivation (Phosphorization) |

Colorless or light gray layer | Suitable for the situation of short-term transportation and storage. | ≤2µm |  |

| Micro Bluing | Colorless or light blue layer | Suitable for the situation of short-term transportation and storage. | ≤2µm |  |

| Curie Point | ℃ | 310~370 |

| Reversible temp coeffcient of Br 20-120℃ | %/℃ | -0.1~-0.13% |

| Reversible temp coeffcient of Hcj 20-120℃ | %/℃ | -0.4~-0.7% |

| Density | g/cm3 | 7.3~7.7 |

| Vickers hardness | Hv | 500~700 |

| Bending strength | Mpa | 150~400 |

| Compressive strength | Mpa | 800~1250 |

| Specific resistiance | μΩcm | 110~170 |

| Thermal conductivity | W/(m.℃) | 5~15 |

| Coefficient of thermal expansion | 10-6/℃ | 4~9 |

| Coefficient of thermal expansion | 10-6/℃ | -2~0 |

| Specific heat | J/(kg.℃) | 350~550 |

| Young’s modulus | GPa | 140~170 |