Your current browser version is too low, in order to bring you a better browsing effect, please use a higher version browser

Walk into any power equipment maintenance room and you’ll probably see shelves stacked with copper busbars, steel brackets, and the occasional bin of brass fittings. But tucked away, often under lock and key, are the parts made from tungsten copper alloys. These aren’t just fancy alternatives—they’re the parts that handle the jobs ordinary metals can’t. At AT&M’s workshop, there’s a place where fresh W-Cu bars cool after sintering. They look unassuming, like dull silver bricks, but each carries its own story: W90Cu10 for brutal heat, W75Cu25 for balanced work, W50Cu50 for when conductivity is king.

Before diving into the nitty-gritty, it’s worth saying—this isn’t some lab curiosity. Tungsten copper alloys are in live systems right now, doing real work.

Tungsten is the heavyweight champion of density and heat resistance. Copper, on the other hand, is the easy-going neighbor who’s great at carrying current. Fuse the two, and you get a composite that can conduct electricity and stay rigid at temperatures where copper alone would sag. Engineers like to say it’s “strength married to conductivity,” though that undersells how well these materials survive abuse.

In a high-voltage breaker, arcs can hit 6,000 °C in milliseconds. Copper alone can’t take that—its melting point is barely over 1,000 °C. Tungsten stands strong up to about 3,420 °C. In W-Cu alloys, the tungsten skeleton holds the shape while copper quickly spreads heat away. It’s like having a firefighter inside the part, constantly cooling and keeping the structure intact.

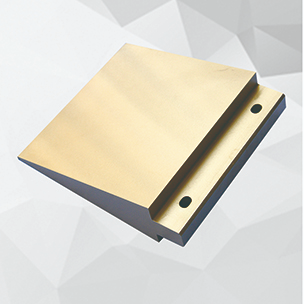

Depending on the mix, you get thermal conductivities from about 180 W/m·K to 300+ W/m·K. That’s why you’ll see W50Cu50 plates under high-power transistors, quietly pulling heat away so the electronics can keep ticking without drama.

It’s one thing to look good on paper. It’s another to keep working after thousands of stress cycles.

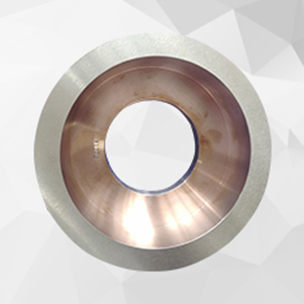

W-Cu Alloys from AT&M are often fitted into main contacts in switch gear. These contacts open and close more times than you’d want to count. I’ve seen one breaker in a power substation run the same W75Cu25 contacts for over 12 years—still passing inspection.

In vacuum interrupters, contact erosion is inevitable. But with tungsten copper, the rate slows enough that maintenance teams can double their service intervals. One technician I met said he “barely remembers the last time” they had to pull those contacts out for replacement.

In a factory test, AT&M’s W75Cu25 parts in a 12 kV breaker hit 20,000 cycles with minimal pitting. Copper-chromium contacts under the same test didn’t even reach 8,000 before showing significant wear.

It’s easy to think these alloys are only for power utilities, but they’ve found a home in plenty of other places.

Electrical discharge machining eats electrodes for breakfast. W-Cu electrodes stay sharp longer, which means mold makers spend more time cutting and less time swapping tools. A die shop in Guangdong reported cutting electrode replacements by 40% after switching to AT&M’s grade.

In RF amplifiers, excess heat is the silent killer. W-Cu alloy heat spreaders keep things stable, so your signal doesn’t drift. Laser cutting systems use them too—because nobody likes a beam that suddenly goes out of focus mid-job.

Radar transmitters in fighter jets, satellite electronics—these systems face both vacuum and intense heat. W-Cu alloys shrug off the challenge, staying dimensionally stable over years of service.

You could put copper or steel in the same role, but you’d be signing up for more downtime.

Pure copper parts might need changing every few thousand cycles. W-Cu can last multiple times that. It’s the difference between calling maintenance once a season versus once every few years.

For utilities managing hundreds of breakers, fewer replacements mean more than just material savings—it’s fewer trucks rolling out, fewer man-hours, fewer headaches.

Yes, W-Cu alloys cost more upfront. But over the lifespan of a power system, they often pay for themselves in reduced maintenance and downtime.

The process is more craftsmanship than mass production.

High-purity tungsten and copper powders are blended to spec. AT&M’s technicians keep a close eye on particle size and moisture—too fine or too damp and the final part can develop hidden flaws.

The tungsten skeleton is sintered at over 2,000 °C, then infiltrated with molten copper under vacuum. Timing is everything; a second too long and the bond changes, a second too short and the copper doesn’t fully penetrate.

Density, conductivity, strength—each batch is tested before leaving the plant. Inspectors can reject parts that looked perfect, just because a resistance reading was slightly off.

Picking the wrong grade can cost you performance, or worse, cause premature failure.

High tungsten means better heat resistance. More copper means better conductivity. The balance depends on your job’s priorities.

Arc contacts often lean toward W75Cu25 for balanced performance. Heat sinks might favor W50Cu50 for maximum thermal flow.

If you need something out of the ordinary, AT&M can machine custom shapes or tweak compositions.

The needs of modern tech are pushing these alloys into new roles.

Smaller devices, more power—W-Cu alloys can handle the cramped quarters without overheating.

Wind and solar power systems are turning to W-Cu for inverters and storage solutions.

AT&M reclaims tungsten and copper from scrap, reducing environmental impact and keeping costs in check.

Q1: Why choose tungsten copper over pure copper for high-voltage switches?

A: W-Cu alloys resist heat and arc erosion far better, meaning fewer replacements.

Q2: Are W-Cu alloys safe for electronic devices?

A: Yes, they are stable and non-reactive in normal operating environments.

Q3: What’s the most common W-Cu composition for arc contacts?

A: W75Cu25 offers a balance of conductivity and arc resistance.

None