Your current browser version is too low, in order to bring you a better browsing effect, please use a higher version browser

Core drilling is a key method for pulling out round samples from tough materials like concrete, stone, or rock layers. It requires tools that stay strong, handle heavy wear, and keep cutting smoothly. In today’s construction and engineering, Diamond Tools have become the top choice because they meet these tough needs. Unlike hammering drills, core drilling uses spinning force and steady pressure. This makes cutting speed and heat control very important.

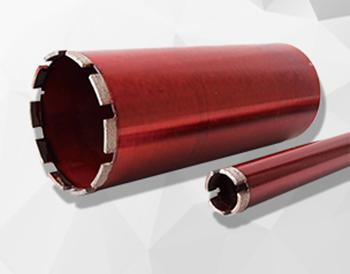

You gain a lot by choosing Diamond Tools over older tools made of carbide or steel. Their incredible strength lets them slice through reinforced concrete and natural stone without bending or breaking. A full range of quality diamond core bits is available for drilling construction materials, including heavily reinforced concrete, stone, and other materials. This strength means you swap tools less often, saving time on the job. Also, Diamond Tools make less shaking and noise. This keeps workers safer and more comfortable.

The power of Diamond Tools comes from the special qualities of industrial diamonds. These include super hardness, great heat movement, and resistance to wearing out. These features allow clean cuts without overheating the material. The base material holding the diamonds is also key. It must let go of worn diamonds at the right pace while keeping new ones ready to cut. This balance ensures steady work.

Getting the right cutting speed and pressure is vital for good core drilling. You need a balance. Too fast can overheat and wear out tools early. Too slow wastes time. Advanced diamond core bits are built to work at many speeds while keeping samples intact.

How well a tool resists wear affects its cost. Strong building methods, like advanced sintering, ensure Diamond Tools last longer and cut well. A tool that stays sharp longer means fewer replacements. This saves money over time.

Accuracy matters a lot when taking samples for rock studies or building checks. Diamond Tools give clean, smooth edges with little chipping or cracking. This ensures you get clear, correct samples for studying layers or checking concrete.

Modern methods like laser welding, sintering, and vacuum brazing make Diamond Tools stronger. A range of high-performance laser-welded blades, advanced laser welding technology, and high tensile steel cores guarantee the safety and cutting performance. These improvements allow tools to handle heavy twisting forces without breaking or losing parts.

Adding tiny crystal alloys to tool bases has changed how tough Diamond Tools are. These materials stay strong under stress while bending just enough. Special non-crystal metals also help by wearing evenly, making tools last longer even in rough conditions.

If you need reliable core drilling tools, check out the Diamond Tools from Advanced Technology & Materials Co., Ltd. (AT&M). Their lineup includes laser-welded blades, sintered blades, vitrified grinding wheels, V-Tech solutions based on vacuum brazing innovation, and special sapphire grinding tools. These are made for precise jobs in many fields.

AT&M’s diamond core bits work well on tough materials like reinforced concrete and natural stones. They cut fast and accurately. A full range of quality diamond core bits is available for drilling construction materials, including heavily reinforced concrete, stone, and other materials. Their design clears debris well and keeps heat low. This helps the bits last longer during deep drilling.

Hard metals like tungsten or molybdenum are added to tool bases to handle high heat from dry or fast drilling. These metals keep tools stable and strong, even when cutting through dense rocks or strong concrete.

Fine alloy powders spread evenly in the tool’s base. This leads to steady wear across the cutting edge. It makes tools last longer and clears waste better, which is important for long drilling jobs.

In surveys where knowing ground layers is critical, Diamond Tools offer great accuracy with little disturbance to the ground. You get clean core samples that show true underground conditions. This is key for checking land or finding minerals.

When building tunnels or bridges through hard rocks like granite, regular tools are too slow and imprecise. Diamond Tools cut faster and need fewer changes, saving time on big projects.

In deep wells with hot, rough rock layers, Diamond Tools keep working well without needing frequent swaps. This saves time for every meter you drill.

You must choose drill features like segment height, grit size, and bond strength based on the ground you’re drilling. For example, soft bonds work better on hard materials because they release fresh diamonds faster. Hard bonds are better for softer, gritty materials.

Don’t just look at the starting price. Think about how long a tool lasts and how much work it does. A high-quality diamond core bit may cost more at first but can outlast several cheaper ones. Available qualities of economic-standard-premium satisfy all the cutting requirements.

Q1: Why are Diamond Tools better for core drilling?

A: Their super hardness cuts tough materials well while staying precise. They also shake less, making work safer for users.

Q2: How do I pick the right diamond drill bit for my job?

A: Match the bond type (soft or hard), segment height, and grit size to the material’s hardness. Look at long-term cost, not just the upfront price.

Q3: Can Diamond Tools be used for both wet and dry drilling?

A: Yes, Diamond Tools work for both wet and dry drilling. Wet drilling uses water to cool the tool and clear debris, which helps the tool last longer. Dry drilling is useful in places where water isn’t available.