Your current browser version is too low, in order to bring you a better browsing effect, please use a higher version browser

When someone says “Refractory Metals & Products,” most people’s eyes glaze over. It sounds like something locked away in a lab, right? The truth is, these metals are everywhere. Not just in rocket nozzles or deep inside nuclear reactors—though they’re there too—but also in things you use without even thinking about it. The frame of your laptop screen, that odd part of the car’s braking system, a small shield inside a microwave oven, and some of these are made from refractory metals.

Through AT&M’s factory, the air smelled faintly metallic, and somewhere a furnace hissed. On a rack, tungsten bars glowed a muted cherry red—fresh from a sintering cycle. A machinist tapped one with a gloved finger, testing the sound. “Good tone,” he said. That meant no hidden cracks. That’s the kind of everyday expertise you don’t get from a textbook.

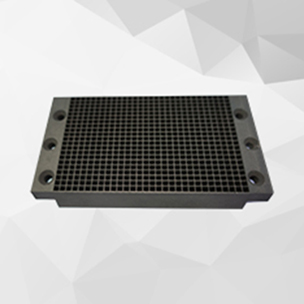

In plain terms, these are a small group of metals—tungsten (W), molybdenum (Mo), tantalum (Ta), niobium (Nb), rhenium (Re)—that can take punishment. They melt at crazy-high temperatures, shrug off corrosion, and don’t deform easily. AT&M has taken these raw elements and turned them into all sorts of Refractory Metals & Products: tungsten heavy alloys, tungsten copper (W-Cu) composites, molybdenum copper (Mo-Cu) parts, and more.

Melting points north of 2,000°C. High density—tungsten feels like a rock in your hand, heavier than it should be. Strength that doesn’t quit, even when the metal is glowing hot.

Tungsten and molybdenum are the workhorses. Tantalum’s the go-to for nasty chemical environments. Niobium finds its way into superconductors. Rhenium? That’s your extreme heat creep-resistant specialist.

Compared to stainless steel, these metals don’t slump at high heat. They expand less, which means tight tolerances stay tight. And corrosion? They can sit in acids that would eat steel alive.

It’s not just aerospace and defense—though they take a big slice. Electronics, energy, or healthcare, if there’s heat, wear, or a chemical bath involved, there’s probably a refractory metal part in there somewhere.

Think tungsten heavy alloy counterweights in aircraft tail sections. Or molybdenum alloy nozzles in missiles. These aren’t parts you swap like a car tire—they’re designed for the long haul.

Molybdenum sputtering targets coat glass for touchscreens. Tungsten-copper contacts in high-voltage switches survive arc after arc without welding themselves shut. I once saw a molybdenum strip in a smartphone display—thin as paper, stable after thousands of heat cycles.

Inside coal-fired plants, molybdenum alloy furnace boats carry ceramic parts through kilns at 1,500°C. Tungsten electrodes hold up under repeated welding arcs without losing shape.

This is where things get fun. You might have used them today without knowing.

Tungsten plates in X-ray machines shield against radiation. AT&M machines them down to within ±0.05 mm. Tantalum, meanwhile, sits quietly inside surgical implants, resisting corrosion from body fluids.

Molybdenum strips in LCDs keep the colors even. Tungsten-copper plates in induction cooktops spread heat evenly, so your food cooks without hot spots.

Tungsten-based ABS brake parts keep their shape under sudden stops. In EVs, molybdenum connectors in battery packs handle the heat from fast charging without breaking a sweat.

This isn’t simple melting and pouring—it’s a careful, staged process.

Tungsten starts as wolframite ore, roasted and reduced to powder. Molybdenum comes from molybdenite concentrate, purified through roasting and leaching. A little contamination here can ruin a whole batch.

AT&M’s powder presses compact the powders, then sintering furnaces heat them to 2,400°C. Rolling mills turn billets into thin strips with mirror-like surfaces.

Precision molybdenum strips are checked for flatness within ±5 microns. Ultrasonic tests catch hidden flaws. I once watched an inspector reject a piece that looked perfect—because the sound wave test said otherwise.

Simple: they last longer, even when things get ugly.

Tungsten heavy alloys in jet turbines hold their shape well past 1,000°C, while most metals would creep and deform.

In industrial presses, molybdenum dies outlast steel ones three to one. That’s less downtime and fewer headaches.

From shielding in hospitals to contacts in power grids, Refractory Metals & Products are chosen when failure isn’t an option.

They don’t just sell metal—they engineer it, from powder to polished part.

Tungsten Heavy Alloys, W-Cu Alloys, Mo-Cu Alloys, Rhenium Alloys, plus rolled tungsten and molybdenum sheets, rods, and wires.

Need a tungsten heavy alloy counterweight with a very specific density? They’ll make it. Need a molybdenum-copper connector at 0.12 mm thickness? It’s doable.

ISO9001 and aerospace-grade approvals back up the production line.

The demand curve’s pointing up.

Electric vehicles need tungsten in battery modules. 5G networks use molybdenum in their base stations. Surgical robots? Yep, there too.

Better powder metallurgy. Additive manufacturing for complex shapes. Finer grain structures for longer fatigue life.

AT&M’s recycling lines turn tungsten and molybdenum scrap into new products, trimming costs and cutting waste.

Q1: What makes refractory metals different from ordinary metals?

A: Their ability to stay strong under extreme heat and resist corrosion. They keep going where others fail.

Q2: Are these metals safe in consumer products?

A: Yes—tungsten in X-ray shields blocks radiation; molybdenum in screens is stable and safe.

Q3: Does AT&M supply both raw and finished products?

A: Both. Sheets, rods, wires, and fully machined components.

None